The Trust was established in 1983 to keep the archives of the Leeds Model Company and R. F. Stedman & Company. Today the Trust provides a service of spares, repairs and technical advice to LMC enthusiasts and continues to promote interest in and appreciation of the products of The Leeds Model Company, founded by Rex Stedman in 1912, and which ceased to trade in 1967. If you have any questions about the Trust, would like to enquire for specific parts, place an order or make a comment please send us an email to dkp5506@yahoo.com

David K. Peacock, Co- proprietor, Trustee and Archivist

Marcus D. Peacock, Co-proprietor and Trustee

Latest News

The Horden Layout has a new keeper!

It gives much pleasure to report that the Horden layout has been purchased by a leading member of the Australian model railway fraternity. He plans to house the layout locally to his home in Victoria, and investigate the possibility of making it portable to take around to shows, exhibitions and the like.

Our thanks go to Glyn Eden who over the past many years has persevered with the restoration of this historic model railway, and our very best wishes go to his successor now working towards the 100th year of the Horden layout in 2028. A centenary few could have imagined would ever come about!

Rex Stedman with the layout in 1928

Station Accessories 1924

The 1924 catalogue, entitled Leeds Model Company (1924) was very much enlarged from that of 1922/3, reflecting the beneficial financial impact of the new association of the Bristol Model Company with the LMC. The catalogue contained an additional separately printed page, 74A, which detailed a newly introduced range of six station accessories.

Pictured here in an original box the pieces are; a weighing machine, a platform ticket machine, a machine selling small bars of Nestles milk chocolate, a nameplate stamping machine, a G.P.O. pillar box and a multi-sweet, cigarette and match vending machine.

In a separate leaflet LMC claimed the models to be ‘exact replicas of the machines so familiar on railway stations’. A good number of sets would surely have been sold up to the early 1930s, after which they were missing from the catalogue. A few complete sets do appear from time to time, odd items generally in poor condition and without boxes turn up with reasonable regularity, but there are also later productions of all but identical copies too. The original LMC items, other than the pillar box have L.M.C. embossed on the backs of the pieces. I am indebted to Jean-Claude L’Hostis for this picture. He has painstakingly collected the six pieces and a box in reasonable condition to contain them

Train sets in the 1920s!

Until a few days ago I knew only of train sets being offered by the Leeds Model Company from the end of the 1940s. You can imagine my surprise, when presented with a well-preserved catalogue from 1921, to find stapled with the printed pages a duplicated supplement offering – yes - train sets!

A ‘Large’ set comprising a 4-4-0 loco, one coach and one brake van and an oval of track (16 pieces) for £5-10 -0 (£5.50)

A ‘Small’ set comprising an 0-4-0 ‘Baby’ (sic) tank, three trucks one brake van and the same oval of track £5-5-0 (£5.25).

There is no mention the drive, but at the time only clockwork mechanisms were advertised in the catalogue, the first mention of electric drive being available appearing in the catalogue for 1924.

There is similarly no mention of livery, and as with the 1940s sets one imagines the selection might well have been made from the slowest selling liveries of the locomotives available off the shelf.

The 4-4-0 would have been the Series 1 standard, then priced at £3-3-0, (£3.15) and the 0-4-0 the ubiquitous ‘Donkey’ then priced at £2-7-6, (£2.38). The first (NE) litho coaches and pre-grouping litho wagons were available, but their prices and the price of the track packages added to that of the locomotives hardly made these sets a bargain buy.

A Great Gathering

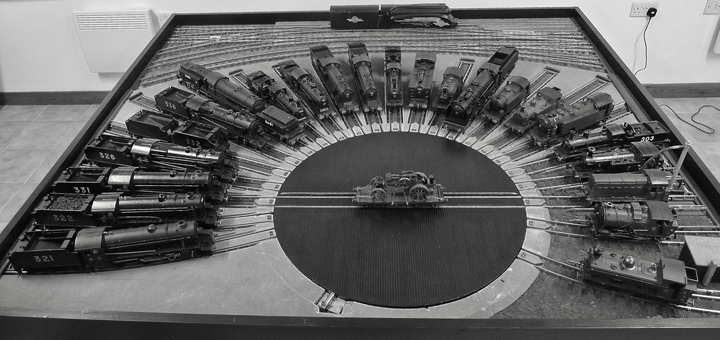

The promised Gathering of Geoffrey Keen’s surviving K-Lines and Pantry Dockyard locomotives took place on March 5th. The Model Railway Club and nine K-Lines enthusiasts either dug deeply into their storage cupboards or raided their layouts to produce no less than fifteen ‘K’ locomotives and eight of Mrs. Keen’s ‘Pantry Dockyard’ railway, led by the diminutive 0-4-0T ‘Bene Stalk’, (named after the slender Alma Keen). Along with these came more than fifty items of rolling stock, coaches, the oldest dating from 1918, and an amazing variety of wagons, the most elegant being Stedman’s model of a wagon mounted traction engine, shown here centre stage on the magnificent Beeson-built turntable.

Unfortunately we could not finally secure a loan of the Stedman built LNER Garratt from the NRM, Twining’s model of the loco can be seen on the seventh road from the left. Two of Keen’s Pacifics ‘Honourable Knights of the Turntable’ were present, the Marescot No 340, ‘Sir Wadel de Gravity’ and the streamliner No 342, ‘Sir Reliff de Tanque’. Bob Vickery through whose efforts the turntable has been preserved gave an enjoyable and informative account of his time on the K-lines layout at Hythe, saying that he last saw the turntable with all roads occupied in 1958, altogether quite a memorable day for him!

More detailed articles are planned for publication later.

Phto: Peter Beale

Phto: Peter Beale

The shelves are filled!

With much help from my grandson Luca the shelving on the back wall of the train room is now filled out with all but a few items of the model collection. This picture shows the longer of the two shelves. I had calculated the length of run to display every item, but the spacing between the shelves would have been insufficient to safely handle taller items, coaches, vans and locomotives on and off the shelves. Some locomotives thus remain in the display cabinet in the house, but they will turn by turn be brought out for running sessions, which like those already featured will appear as videos on this website in due course of time.

For a good while now I have been looking to find a home for the archive – a museum or similar where the models would be on display, available to be run, and that there would be access to the ephemera, drawings and the like. Sadly, I have had no success thus far, and so what I have now in the train room is the best that can be done for the time being. I hope you will enjoy the videos as they come out.

An extensive LMC archive from the Dutch HRCA

I continue to be delighted at the work put in by Hans van Dissel of the Dutch HRCA to record on their website adverts, editorials and correspondence related to the Leeds Model Company. Starting from 1915, Hans listings are now into the 1950s, and a most interesting story they make. All but a few of the items he displays are held in the Trust archives from the combined collections of Rex Stedman and later his son Adrian, but they are not as readily available to view. To see the Dutch collection please go to

With their kind permission this link will also be added to the archive section of our website.